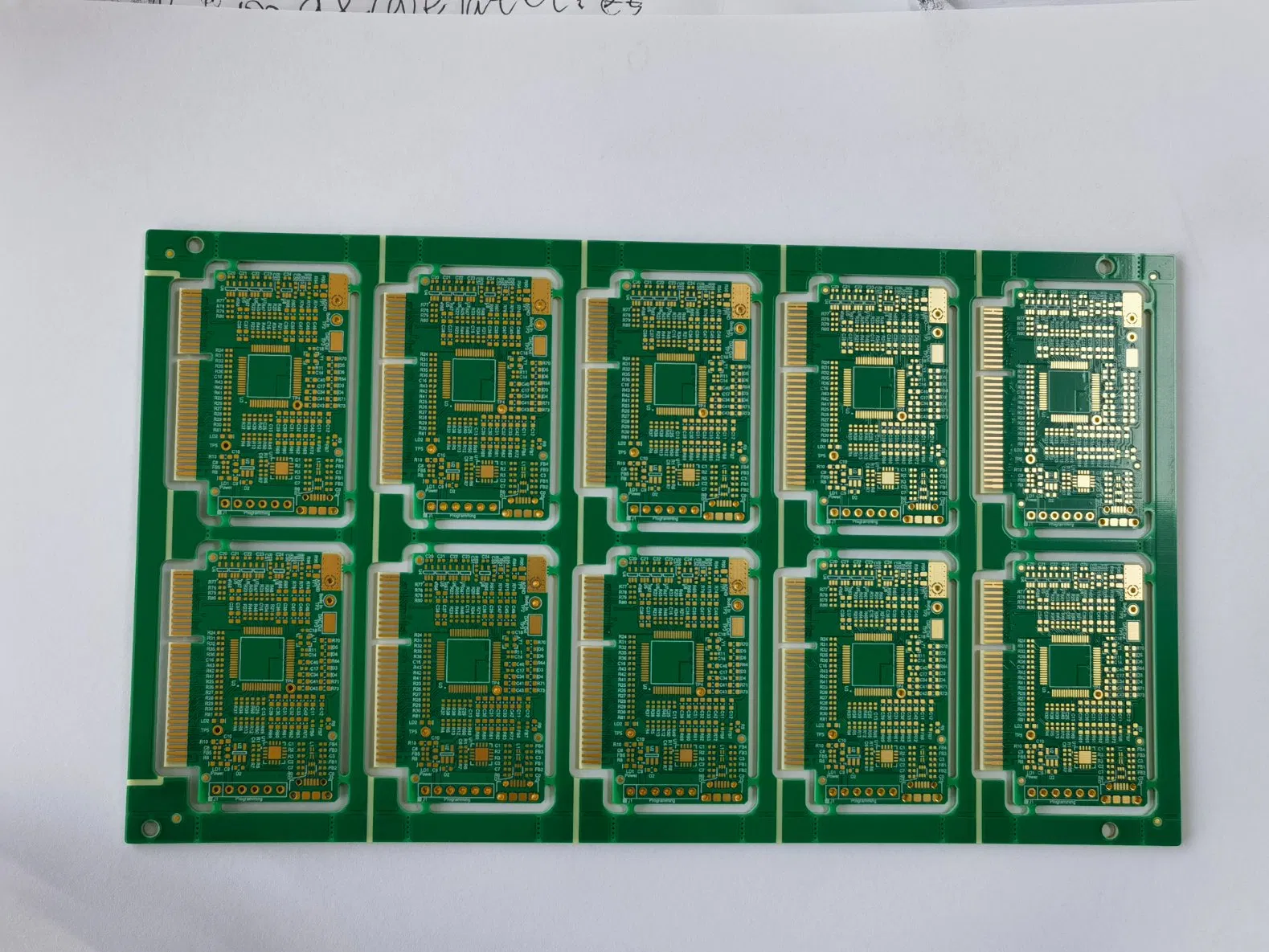

Printed circuit boards (PCBs) are the backbone of modern electronics, serving as the foundation upon which electronic components are connected and communicate. Their applications span across virtually every industry, from the consumer gadgets we use daily to the complex machinery driving industrial operations. High-quality circuit boards are crucial for ensuring reliability, performance, and longevity in these diverse applications. This blog post will explore the vast landscape of PCB applications, highlighting their significance in consumer electronics, industrial equipment, and beyond.

What are High-Quality Circuit Boards?

High-quality circuit boards are more than just a means of connecting electronic components; they are meticulously engineered platforms designed to meet stringent performance and reliability standards. These PCBs are manufactured using premium materials, advanced fabrication techniques, and rigorous quality control processes. Key attributes of high-quality circuit boards include:

Durable Materials: Use of high-grade laminates, copper, and other materials that can withstand extreme temperatures, harsh chemicals, and rough handling.

Precise Design and Manufacturing: Accurate trace routing, impedance control, and adherence to design specifications to ensure optimal signal integrity.

Robust Construction: Ability to endure shock, vibration, and other environmental stressors, making them suitable for demanding applications.

Applications in Consumer Electronics

Consumer electronics are ubiquitous in modern life, and PCBs are at the heart of nearly every device we use. From smartphones and laptops to smart TVs and wearable gadgets, high-quality circuit boards are essential for delivering the performance and functionality that consumers demand.

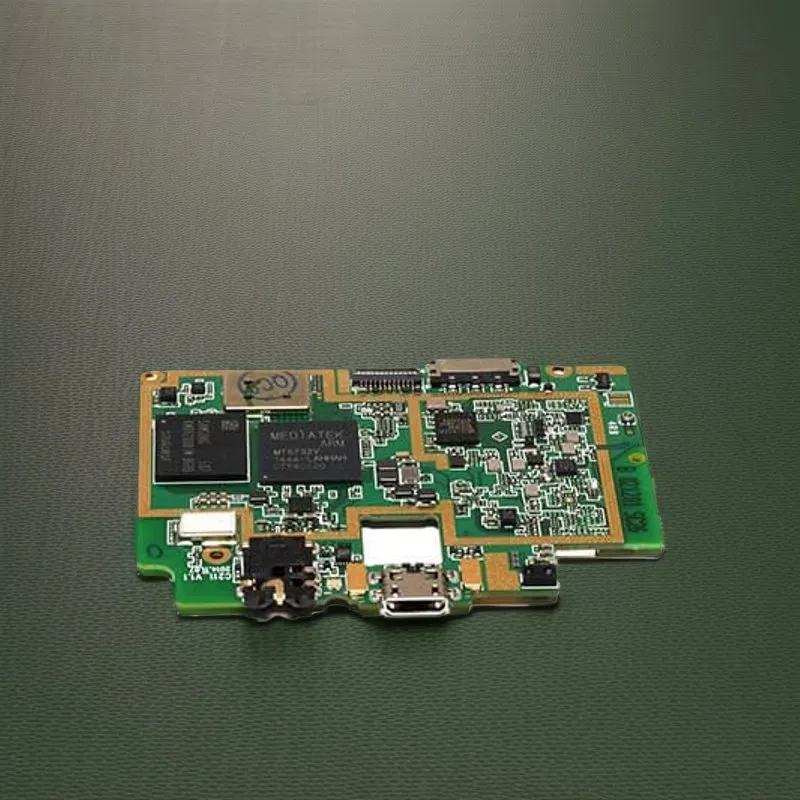

Smartphones and Mobile Devices: PCBs in smartphones enable complex functions like cellular communication, data processing, and multimedia playback. High-Density Interconnect (HDI) PCBs are often used to accommodate the dense circuitry required in these devices.

Laptops and Computers: PCBs in laptops and computers support the operation of processors, memory modules, and peripheral devices. Multi-layer PCBs are commonly used to handle the high density of components and signal routing.

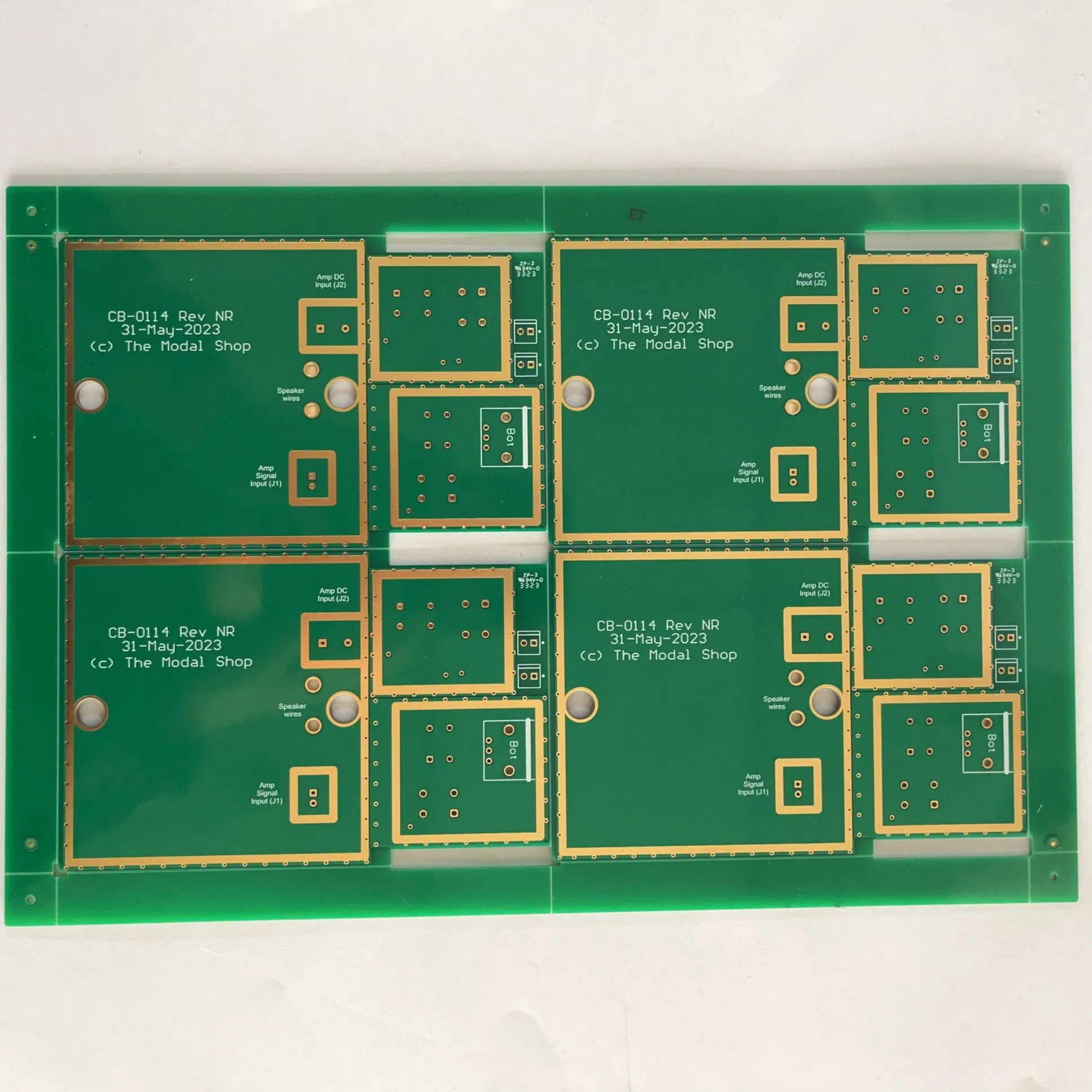

Home Entertainment Systems: Smart TVs, radios, speakers, and gaming consoles rely on PCBs for audio and video processing, connectivity, and control functions.

Wearable Devices: Fitness trackers, smartwatches, and other wearables utilize PCBs to monitor health metrics, provide notifications, and enable wireless communication. Flexible and rigid-flex PCBs are often employed to fit the compact and ergonomic designs of these devices.

Applications in Industrial Equipment

In the industrial sector, PCBs are integral to the operation of machinery, control systems, and monitoring equipment. These applications often demand PCBs that can endure harsh conditions, extreme temperatures, and continuous operation.

Manufacturing Equipment: PCBs are used in automated machinery, robotic systems, and control panels to manage production processes and ensure precision.

Power and Energy Systems: High-current PCBs are essential for power converters, power supplies, and energy management systems. These PCBs often feature heavy copper traces to handle high current loads and provide thermal resistance.

Aerospace Components: Aerospace devices need PCBs that comprise materials that can tolerate vibration and other harsh conditions. Also, some aerospace device function in the outer space and as such, they must be very durable.

Applications in Medical Devices

The medical device industry relies heavily on PCBs for a wide range of equipment used in monitoring, diagnosis, and treatment. These PCBs must adhere to strict quality standards and regulatory requirements to ensure patient safety and device reliability.

Diagnostic Equipment: PCBs are used in imaging systems (MRI, CT scanners), laboratory analyzers, and diagnostic tools to provide accurate and timely results.

Monitoring Devices: PCBs in health monitoring devices, such as blood glucose monitors and heart rate sensors, enable continuous monitoring and data transmission.

Therapeutic Equipment: PCBs are essential components in therapeutic devices, including infusion pumps, ventilators, and pacemakers, delivering precise and controlled treatments.

Applications in Renewable Energy

PCBs play a significant role in renewable energy technologies, facilitating the efficient generation, distribution, and monitoring of clean energy.

Solar Panels: PCBs are used to connect solar cells, integrate sensors, and monitor system performance. They help improve system reliability and withstand tough environmental conditions.

Wind Turbines: PCBs are essential for control systems, power converters, and monitoring equipment in wind turbines, ensuring efficient energy conversion and reliable operation.

Energy Storage Systems: PCBs are used in battery management systems, power inverters, and charging infrastructure for energy storage solutions, optimizing energy consumption and ensuring efficient operation.

The Manufacturing Process of High-Quality PCBs

The manufacturing of high-quality PCBs involves a series of complex processes, each requiring precision and attention to detail.

Design and Layout: PCB designers use specialized software to create the circuit layout, considering factors such as component placement, trace routing, and signal integrity.

Material Selection: High-quality materials, such as FR-4 epoxy resin, copper foil, and high-temperature laminates, are selected based on the application requirements.

Fabrication: The PCB is fabricated using techniques such as etching, drilling, and plating to create the circuit patterns and interconnections.

Assembly: Electronic components are precisely mounted on the PCB using automated robotic systems and then soldered to create electrical connections.

Testing and Inspection: Automated optical inspection (AOI) and automated test equipment (ATE) are used to detect manufacturing defects and verify the electrical performance of the PCB.

Conclusion

High-quality circuit boards are the cornerstone of modern electronics, enabling the functionality, performance, and reliability of devices across a wide range of industries. From consumer gadgets to industrial machinery and medical equipment, PCBs play a critical role in shaping our world. As technology continues to advance, the demand for high-quality circuit boards will only increase, driving innovation and progress in every sector. With companies like Zinpon Electronics Co, Ltd committed to delivering excellence in PCB design and manufacturing, the future of electronics is bright.