The modern automobile is a complex network of electrical and electronic (E/E) components. From the engine and transmission to safety systems and infotainment, these components rely on a reliable and efficient system for power distribution and signal transmission. This is where the auto wiring harness comes in. Acting as the vehicle's central nervous system, the wiring harness connects all the electrical and electronic components, ensuring they function seamlessly. This blog post explores the multifaceted uses of auto wiring harnesses in automotive engineering, highlighting their importance, design considerations.

What is an Auto Wiring Harness?

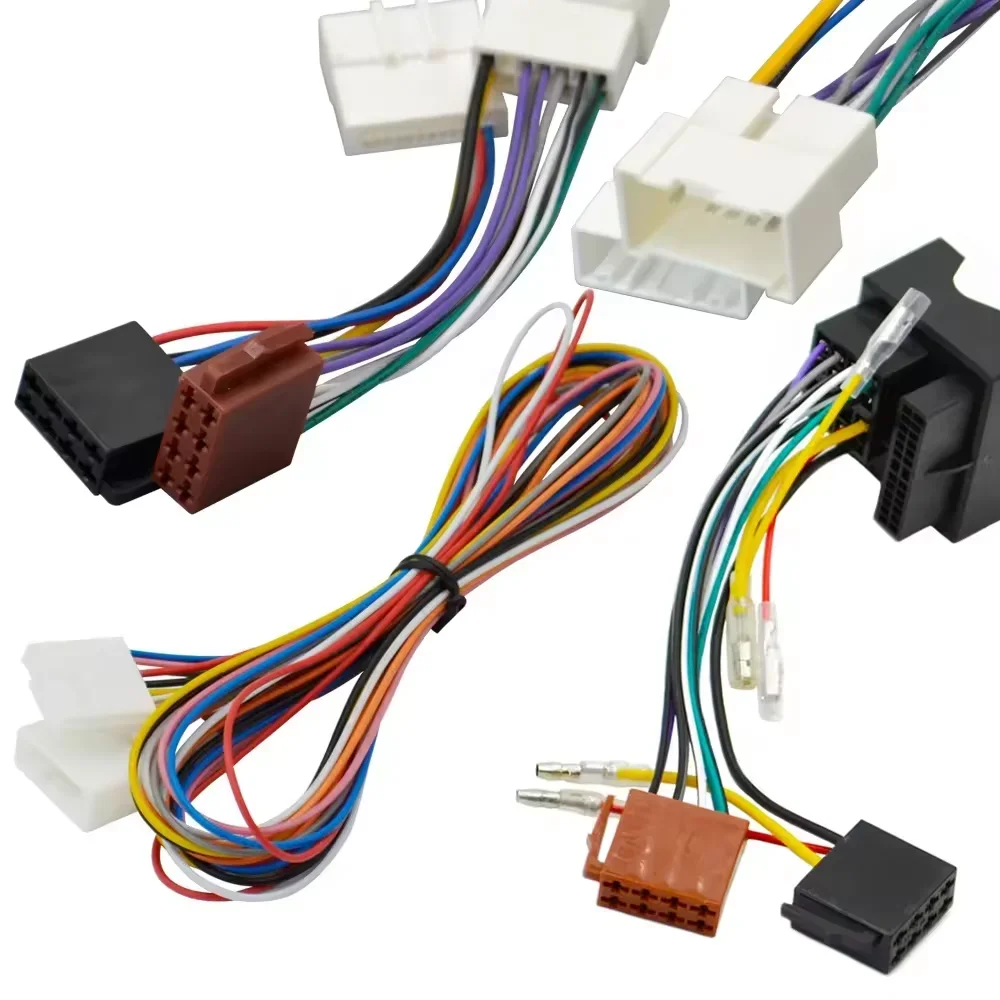

An auto wiring harness is an assembly of wires, terminals, and connectors that transmits electrical power and signals throughout a vehicle. Instead of loose wires running throughout the vehicle, the wiring harness bundles these wires together, protecting them from abrasion, moisture, and vibration. This organized system improves reliability, reduces the risk of short circuits, and simplifies installation and maintenance.

Key Functions of Auto Wiring Harnesses

Auto wiring harnesses perform several critical functions in a vehicle's electrical system:

Power Distribution: Delivering electrical power from the battery and alternator to various components, such as lights, motors, and electronic control units (ECUs).

Signal Transmission: Transmitting signals between sensors, ECUs, and actuators for controlling various vehicle systems, such as the engine, transmission, braking, and steering.

Data Communication: Facilitating data communication between different ECUs and systems, enabling advanced features such as diagnostics, telematics, and advanced driver-assistance systems (ADAS).

Grounding: Providing a common ground connection for all electrical components, ensuring proper circuit operation and minimizing electrical noise.

Applications of Auto Wiring Harnesses in Vehicles

Auto wiring harnesses are used in nearly every part of a vehicle4. Here's a breakdown by area:

Engine Compartment: Connecting the engine control unit (ECU), sensors (e.g., temperature, pressure, speed), fuel injectors, ignition system, and other engine-related components. These harnesses are designed to withstand high temperatures and vibrations.

Chassis: Linking components such as the anti-lock braking system (ABS), electronic stability control (ESC), power steering, suspension sensors, and lighting systems. These harnesses are often exposed to harsh environmental conditions.

Vehicle Body: Connecting the lighting systems (headlights, taillights, turn signals), power windows, door locks, mirrors, infotainment system, climate control, and other interior components. These harnesses often run through tight spaces and must be flexible and durable.

Dashboard: Connecting the instrument cluster, switches, controls, and other dashboard components.

HVAC System: Connecting components in the Heating, Ventilation, and Air Conditioning system. These are optimized for moisture resistance.

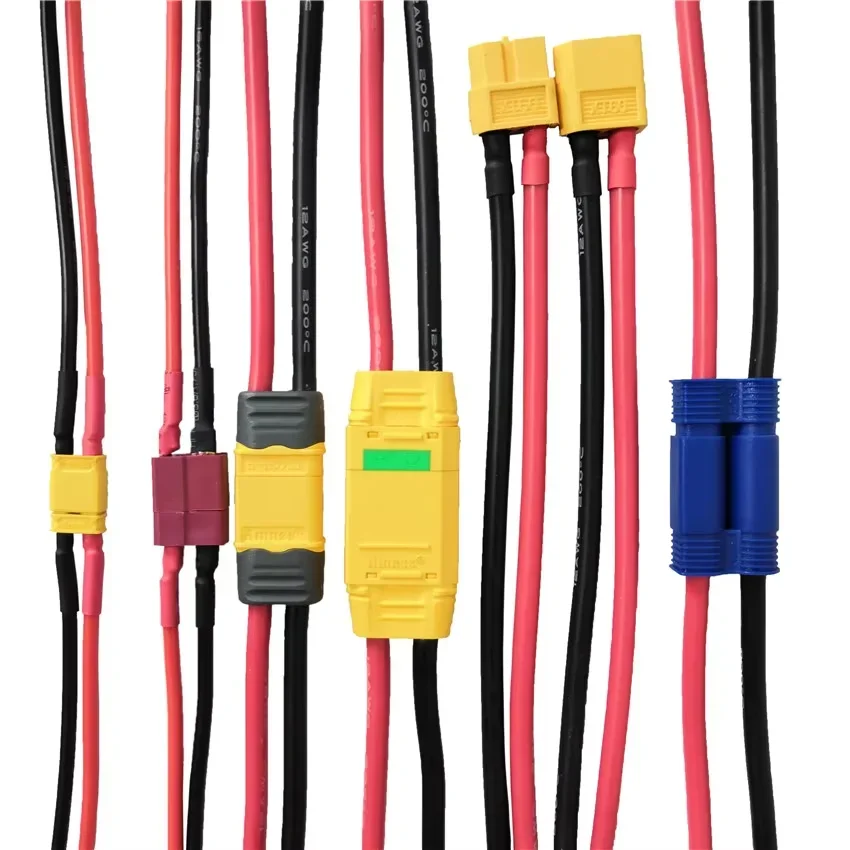

Electric and Hybrid Vehicles: In addition to the above, EVs and hybrids require specialized harnesses for the high-voltage battery, electric motor, charging system, and related components. These harnesses must meet stringent safety standards.

Benefits of Using Auto Wiring Harnesses

Improved Reliability: Bundling wires into a harness protects them from damage and reduces the risk of short circuits.

Simplified Installation: Using a single harness simplifies the installation process compared to running individual wires.

Reduced Maintenance: An organized wiring system makes it easier to diagnose and repair electrical problems.

Optimized Space Utilization: Harnesses are designed to fit within the vehicle's limited space, optimizing space utilization.

Weight Reduction: Optimized harness designs and materials can help reduce the overall weight of the vehicle.

Enhanced Safety: Flame-retardant materials and secure connections minimize the risk of electrical fires.

Performance in Harsh Conditions: Automotive wiring harnesses are made from durable materials, making them perform well under harsh conditions.

Reduced Risk of Shorting: Wire harnesses combine multiple wires into non-flexible bundles, making it safer compared to loose wires and minimizing the risk of shorts in electrical circuits.

Design Considerations for Auto Wiring Harnesses

Designing an auto wiring harness is a complex process that requires careful consideration of several factors:

Electrical Requirements: Determining the appropriate wire gauge, insulation type, and connectors to meet the electrical current and voltage requirements of each circuit.

Environmental Conditions: Selecting materials that can withstand the extreme temperatures, humidity, vibration, and chemical exposure found in automotive environments.

Routing and Space Constraints: Designing the harness to fit within the vehicle's limited space and avoid sharp bends or potential abrasion points.

Safety Standards: Meeting all applicable safety standards to ensure the safety of the vehicle occupants and prevent electrical hazards.

Electromagnetic Compatibility (EMC): Minimizing electromagnetic interference (EMI) to prevent disruptions to sensitive electronic systems.

Weight Reduction: Optimizing the design and material selection to reduce the overall weight of the harness.

Serviceability: Designing the harness for easy access and repair.

Materials Used in Auto Wiring Harnesses

Wires: Copper is the most common conductor material, offering excellent conductivity and flexibility. Aluminum wires are also used to reduce weight.

Insulation: Polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP) are commonly used insulation materials, providing electrical insulation and protection from environmental factors.

Connectors: Various types of connectors are used to connect wires to components, including terminal connectors, housings, and seals.

Terminals: Brass and bronze are typical terminal materials.

Protective Sleeves and Tapes: These materials protect the wires from abrasion, moisture, and heat.

Clamps and Clips: Used to secure the harness to the vehicle body and prevent movement or damage.

Xinying Electronic: Your Partner for Automotive Wiring Solutions

Xinying Electronic Co., Ltd. is a company specializing in providing high-quality auto wiring harness solutions for the automotive industry. While specific details about their offerings require direct confirmation, they likely provide a range of services, including:

Custom Design and Manufacturing: Working with automotive engineers to design and manufacture custom wiring harnesses tailored to specific vehicle requirements.

High-Quality Materials: Using only the highest quality materials to ensure the reliability and durability of their wiring harnesses.

Stringent Quality Control: Implementing rigorous quality control procedures throughout the manufacturing process to meet or exceed industry standards.

Just-in-Time Delivery: Providing timely delivery of wiring harnesses to meet the demands of automotive production schedules.

The Future of Auto Wiring Harnesses

The automotive industry is undergoing a rapid transformation, driven by electrification, autonomous driving, and connected car technologies. These trends are creating new challenges and opportunities for auto wiring harness manufacturers:

Increased Complexity: The number of electrical and electronic components in vehicles is increasing, leading to more complex wiring harnesses.

Higher Voltage Systems: Electric and hybrid vehicles require high-voltage wiring harnesses, demanding new materials and designs.

Data Communication: The need for high-speed data communication is driving the adoption of new technologies such as Ethernet and fiber optics in wiring harnesses.

Weight Reduction: Automakers are demanding lighter wiring harnesses to improve fuel efficiency and reduce emissions.

Automation: Automated manufacturing processes are becoming increasingly important to improve efficiency and reduce costs.

Conclusion

Auto wiring harnesses are essential components in modern vehicles, providing a reliable and efficient system for power distribution and signal transmission. As automotive technology continues to evolve, wiring harnesses will become even more complex and critical. Companies Xinying Electronic Co., Ltd. play a vital role in designing, manufacturing, and supplying high-quality wiring harnesses that meet the demanding requirements of the automotive industry.

Understanding Auto Wiring Harness: Applications and Advantages in Modern Vehicles