In today’s world of advanced industrial manufacturing, circuit boards are the backbone of almost every electronic device and system. From factory automation equipment to consumer electronics, custom printed circuit boards (PCBs) are essential for providing the necessary electrical connections and functionalities that power modern machinery. Whether it’s for controlling motors, managing signals, or enabling communication between components, custom circuit boards are designed to meet the specific needs of complex industrial applications.

In this blog, we’ll explore the importance of custom circuit boards in industrial manufacturing and why companies like Zinpon, a reliable manufacturer of PCBs, are crucial for delivering high-quality, efficient, and tailored solutions.

What are Custom Circuit Boards?

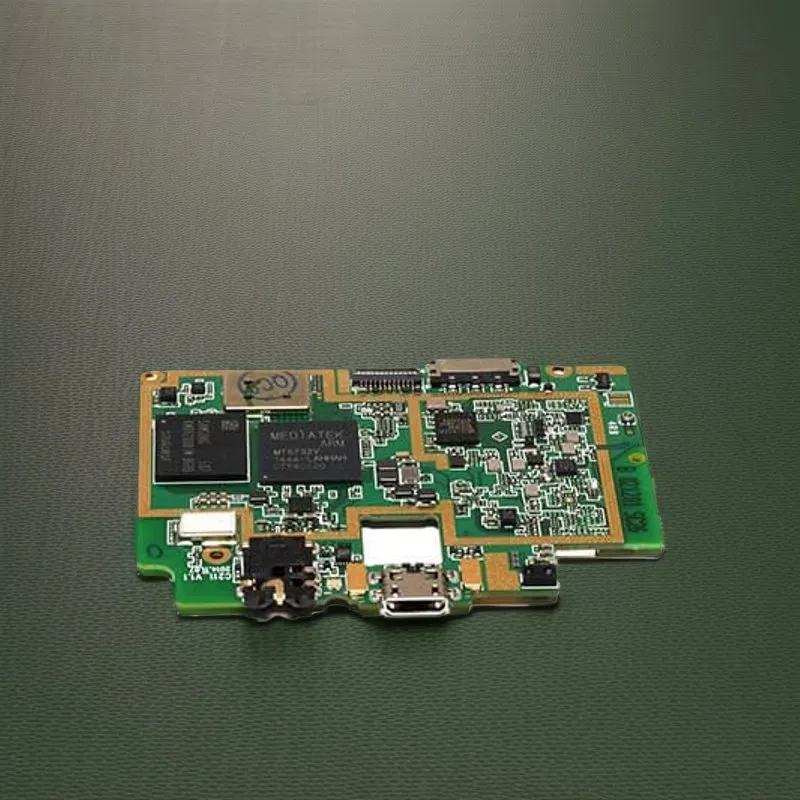

Custom circuit boards (PCBs) are specially designed and manufactured to meet the unique specifications of a particular application or device. Unlike off-the-shelf PCBs, which are mass-produced for general-purpose use, custom PCBs are tailored for specific performance requirements, component layouts, and manufacturing processes.

These PCBs are typically designed using specialized software tools, where engineers define the circuit’s layout, trace widths, component placements, and other crucial factors. Once the design is ready, the PCB is fabricated, assembled, and tested to ensure that it works reliably within its intended environment.

Why Custom Circuit Boards Matter in Industrial Manufacturing

In industrial manufacturing, the demands on electronic components are high. These industries require PCBs that can withstand harsh environments, extreme temperatures, and complex electrical tasks. Here’s why custom PCBs are so important:

1. Precision and Optimization for Specific Applications

Every industrial application has its own set of needs, and off-the-shelf PCBs often can't meet these unique requirements. Custom circuit boards are designed to match the exact specifications needed for a particular piece of machinery or process. Whether it's for power management, signal processing, or controlling sophisticated automation systems, custom PCBs provide the flexibility to optimize the board layout for the most efficient operation.

For example, in automated manufacturing systems, a custom PCB might be designed to control the movement of robotic arms, ensure accurate temperature control in industrial ovens, or manage sensors in a conveyor belt system. With custom design, companies can ensure that all the necessary components are arranged and connected to support the desired functions.

2. Enhanced Performance and Reliability

One of the key benefits of custom circuit boards is their ability to enhance the performance and reliability of industrial systems. Standard PCBs may not be optimized for the specific conditions they’ll be subjected to. In contrast, custom PCBs are carefully engineered to handle the electrical loads, frequencies, and environmental factors unique to the application.

For example, in industrial machinery that operates in high-temperature or high-vibration environments, custom PCBs can be designed with materials that resist heat and physical stress, thus reducing the likelihood of failure. Similarly, custom designs can incorporate additional features, such as built-in protection circuits, to improve the board’s durability.

3. Cost-Effectiveness in the Long Run

While custom PCBs may have a higher upfront cost compared to standard boards, they often lead to significant savings in the long run. This is because custom boards are specifically designed to meet the exact needs of the equipment, minimizing the chances of failures and the need for expensive repairs or replacements.

Additionally, a well-designed custom PCB can streamline the manufacturing process by reducing the number of components required or simplifying the assembly process, thus saving on overall production costs. Over time, the increased reliability and efficiency can lead to reduced downtime and maintenance costs, making custom circuit boards a wise investment.

4. Space Efficiency and Compact Design

Many industrial applications, especially in embedded systems, require compact designs that maximize space utilization. Custom circuit boards allow for more efficient use of space by precisely placing components where they’re needed and reducing unnecessary parts. This compactness is crucial in industries where real estate on machinery or equipment is limited, such as in automated systems or portable devices.

Moreover, custom PCBs allow engineers to integrate multiple functions into a single board, reducing the number of separate components required. This not only saves space but also reduces the complexity of assembly and troubleshooting.

5. Tailored Functionality

In industries where technology and functions are continuously evolving, custom circuit boards allow companies to implement new features, improve performance, or integrate additional capabilities as needed. Custom PCBs can incorporate a wide range of functions, such as:

Power management for energy-efficient operations

Signal processing for better data communication

Temperature regulation for controlling heat-sensitive systems

Safety features, including short-circuit protection or overcurrent detection

Customizing the board allows the specific requirements of industrial systems to be met while enabling future upgrades and technological advancements.

Applications of Custom Circuit Boards in Industrial Manufacturing

Custom circuit boards play a crucial role in various industrial applications. Here are some common areas where these PCBs are used:

1. Automation and Robotics

In manufacturing plants, automation systems and robotic arms rely on custom-designed circuit boards for controlling motors, sensors, and communication networks. Custom PCBs are essential for providing the precise control needed for the robotic system to function correctly. They also help optimize the integration of sensors, feedback loops, and communication protocols.

2. Industrial Control Systems

Custom PCBs are at the heart of industrial control systems, which manage processes such as temperature control, fluid movement, and energy consumption. In these applications, custom boards are designed to handle complex algorithms, interface with external devices, and ensure that systems operate within their optimal parameters.

3. Energy and Power Management

Industries that deal with power generation, renewable energy, or energy storage systems often require custom PCBs to manage the flow of electricity, monitor system health, and optimize energy consumption. Custom circuit boards are particularly valuable in solar power inverters, battery management systems (BMS), and wind turbines, where precision, efficiency, and reliability are crucial.

4. Telecommunications Equipment

Telecommunications systems depend heavily on custom circuit boards to maintain high-speed data transfer, minimize signal loss, and support multiple channels. From network switches to wireless communication devices, custom PCBs provide the electrical connections and signal processing capabilities required for seamless communication.

5. Medical Devices

Custom circuit boards are also used in medical devices that require accurate data processing, signal conditioning, and interface with sensors. In devices such as patient monitoring systems, diagnostic equipment, and infusion pumps, custom PCBs are essential for ensuring safe and reliable operation. These PCBs must meet strict regulatory standards, which makes custom design an important consideration.

Why Choose Zinpon for Custom Circuit Boards?

Zinpon is a reliable and experienced manufacturer of printed circuit boards (PCBs) that specializes in creating custom solutions for industrial applications. Here’s why Zinpon is an excellent choice for businesses looking for high-quality, tailored PCB solutions:

1. Expertise in Custom Design

With years of experience in the industry, Zinpon has the technical know-how to design custom PCBs that meet the most specific and complex requirements. Their team of engineers works closely with clients to ensure that the design, layout, and material choices are optimized for performance and cost-efficiency.

2. High-Quality Manufacturing Standards

Zinpon adheres to the highest manufacturing standards, ensuring that every custom PCB is built with precision, quality, and durability in mind. They use advanced fabrication techniques and quality control measures to guarantee that each board meets strict specifications.

3. Fast Turnaround Times

Understanding the fast-paced nature of industrial manufacturing, Zinpon provides quick turnaround times for custom PCB orders. Their efficient production processes and streamlined logistics ensure that you get your products when you need them, without sacrificing quality.

4. Competitive Pricing

Zinpon offers competitive pricing for their custom PCB manufacturing services. By optimizing the design and production process, they help reduce costs without compromising on the quality or functionality of the board.

5. Comprehensive Support and Service

From initial design consultation to after-sales support, Zinpon offers comprehensive assistance throughout the entire process. Their customer service team is always available to answer questions, provide technical guidance, and ensure that projects move forward smoothly.

Conclusion

Custom circuit boards are essential in industrial manufacturing, offering tailored solutions that optimize performance, reliability, and functionality. Whether you’re in automation, power management, or telecommunications, custom PCBs ensure that your systems perform at their best while meeting the unique demands of your industry.

Zinpon, with its expertise in PCB design and manufacturing, is a trusted partner for businesses seeking high-quality custom circuit boards. Their focus on precision, efficiency, and customer satisfaction makes them a top choice for companies looking to power their industrial processes with reliable and optimized circuit board solutions.

The Role of High-Quality Circuit Boards in Modern Industrial Electronics