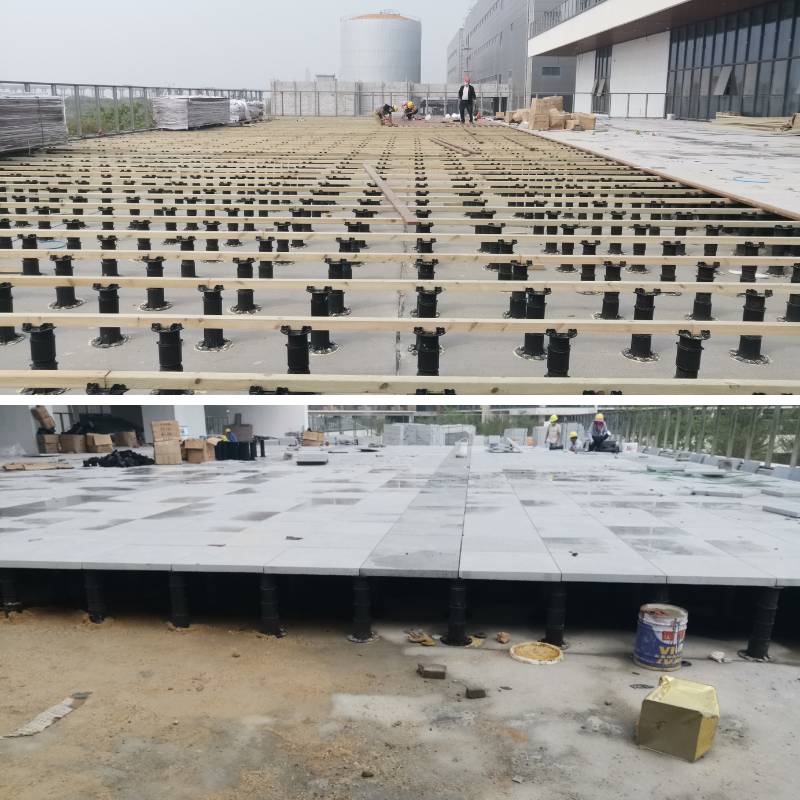

A project site: "Why is this height wrong?"

"The ground drainage is always not smooth, the third time to rework..."

At the construction site, height adjustment, leveling, and support problems often cause delays and cost spikes.

Is there a tool that can be as flexible as building blocks, as strong as steel bars, and can save time and effort?

The answer is —— Adjustable universal support!

First, adjustable universal support: redefine the black technology of "support"

What is the universal support?

It is made of high-strength engineering plastic (high-density polypropylene PP), through the modular design of adjustable support parts + base seat, it can accurately control the height of the object (usually the adjustment range of 28mm-1750mm), suitable for stone, tile, water fountain, plastic wood floor, indoor booth and other scenes, called the "Transformers" in the decoration industry.

Universal support is a new type of building material introduced from Europe, its main characteristics are: quick installation, easy maintenance, strong pressure capacity, high aesthetics and accuracy, long service life, not affected by cold, heat and humidity. For most cities, the use of universal supports is undoubtedly a good way to reduce the load on the city. We are based on the present, looking forward to the future, green, economic, convenient and sustainable development of the method will become the mainstream of construction, it can be predicted that in a few years, universal support will be for the urban greening and our urban space to add more brilliant color.

1. High adjustability:

The universal support can be freely adjusted by rotating threads and other ways, and can be further fine-tuned by gaskets, which can better adapt to different thickness materials or uneven ground to ensure the flatness of the support surface. In contrast, the height of the brick support pier is not easy to control, and is greatly affected by the brick modulus and the mortar thickness, which is easy to have height deviation.

2. Convenient and efficient construction:

The universal support is simple and fast to install, is not limited by weather conditions, and can be installed by adjusting the height, which can effectively shorten the construction period and save a lot of manpower and material resources. In contrast, traditional bricklaying or cement pouring and other processes, the amount of large, high cost, and cement solidification takes time, but also need special maintenance, rainy weather and other bad weather will delay the construction period.

3. Easy maintenance:

When using the universal support, if you need to overhaul the lower pipeline or perform other maintenance work, you only need to lift the covering such as the SLATE to operate, fast and convenient and does not affect the overall structure, which can greatly save maintenance time and costs. However, the support structure constructed by traditional technology has trouble in pipeline maintenance and needs to destroy the original structure, which is time-consuming and laborious.

4. Drainage and caustic problem improvement:

The universal support will be stone and other materials overhead, there is a large space below for water storage and drainage, and the partition can make the stone surface drainage performance is superior, no obvious water, while avoiding the direct contact between the stone and the ground, can effectively reduce the caustic soda phenomenon, is conducive to extending the service life of the stone and maintain beauty.

5. Light weight:

The universal support is generally made of lightweight high-strength materials such as PP and polypropylene, with light weight, small roof or ground load, and less impact on the building structure. Traditional materials such as solid bricks are heavy and will increase the load on the roof or ground.

6. High aesthetics:

Due to the role of the adjustment parts, the stone seam laid by the universal support is neat and uniform, and the overall visual effect is good, which helps to improve the beauty of the landscape or decoration. Brick and other ways of stone seam mainly rely on the level of workers construction technology, appearance effect is uneven.

The universal support has a wide range of applications, which can be applied to building wood flooring and landscape anticorrosive wood overhead laying, can also be used for garden landscape waterscape stone scaffolding laying, and is also used in the construction of exhibition stands and industrial fields. As a utility model material, the universal support is mainly used in construction engineering and industrial fields, which solves the problems of some special engineering construction and later maintenance work, and is a new environmentally friendly auxiliary material in modern construction engineering and industrial use. And can be used in various shapes of the environment, practical function is strong, the future has a good development trend.

1.st, do a good plan

First do a good planning plan, based on the construction of large drawings and processing sheets, familiar with the size and practice of various parts, especially the implementation of the relationship between the ground LED light belt and corners, to avoid problems at the closing.

2.nd, grass-roots treatment

Handle the debris on the square cushion, keep the ground relatively flat, do not appear local ups and downs, avoid the bottom of the base can not be completely in contact with the ground to cause instability, the cement floor matte surface can be. According to the mark on the drawing and the thickness of the stone to determine the height of the universal support, and then through the various parts of the universal support, rotate left and right to adjust the height required by the universal support. However, it is worth noting that do not rotate the universal support too closely, do not screw out the indication range, and operate according to the use method of the product in order to play the best use of the product.

3.rd, check and control the position of the support

According to the construction drawing and the actual size of the square, pull the cross control line on the square, bounce it on the base, and lead it to the bottom of the wall, then find out the surface level, pop the horizontal level line on the wall, and pop the center line of the support for trial arrangement. The granite stone is arranged in order to check the gap between the stone, and check the relative position of the stone and the wall, the lamp belt, the hole, etc.

4.th, the size of the seam

On the one hand, it can deal with the problem of uneven stone specifications, and it is also the reserved position for water supply and drainage, thermal expansion and cold contraction. The gap is mainly controlled by the adjusting parts, and the adjusting parts can be selected according to the actual needs. The adjusting parts can strictly control the seam accuracy and eliminate human factors, so as to achieve the purpose of uniformity in appearance and improve the aesthetic effect, which is also one of the advantages different from the conventional practice.

5.th, check the flatness

First of all, choose a stone, put it down with a level in the diagonal direction, check whether it is smooth, and then determine every 2 stones next to each other. If it is smooth, the water beads in the middle of the level should be in the middle. Finally, check whether the corners are straight, and the effect is very good from the actual test results. The luminaire of the ground LED light belt is customized according to the height of the stone and is located on the universal support. Luminaire related cables, control system, power supply, etc. are laid from the bottom overhead layer, and the surface layer of the lamp belt is independent from the luminaire. The surface layer is made of customized tempered glass, and the stone grooves on both sides of the light belt are used to place the glass. The grooving specification is 10mm, and the glass is fixed on the stone grooves on both sides by weather-resistant glue. On the one hand, this approach ensures that the core components of the lamp belt, namely the lamp, are not damaged by pressure, and more importantly, it is easy to repair, replace the lamp, cable and other work.

6.th, the use of segmentation

Pay attention to the use of segmentation techniques. If you encounter a special installation situation, you can remove a number of segments or pay attention to the use of corners and other parts that do not need to be separated; Similarly, when the base is installed, it can also be removed under special circumstances, such as obstacles at the bottom of the support, which will affect the modulus of the surface stone laying, in which case the corresponding part can be appropriately removed.

7.th, the use of gaskets to deal with the problem of uneven thickness of stone

There are often defects of uneven thickness in the processing of stone. In the process of installing the stone, the universal support can be adjusted by the gasket to eliminate the error of the stone itself. This requires us to adjust the gasket according to the specific situation of the construction site and the difference in stone thickness.