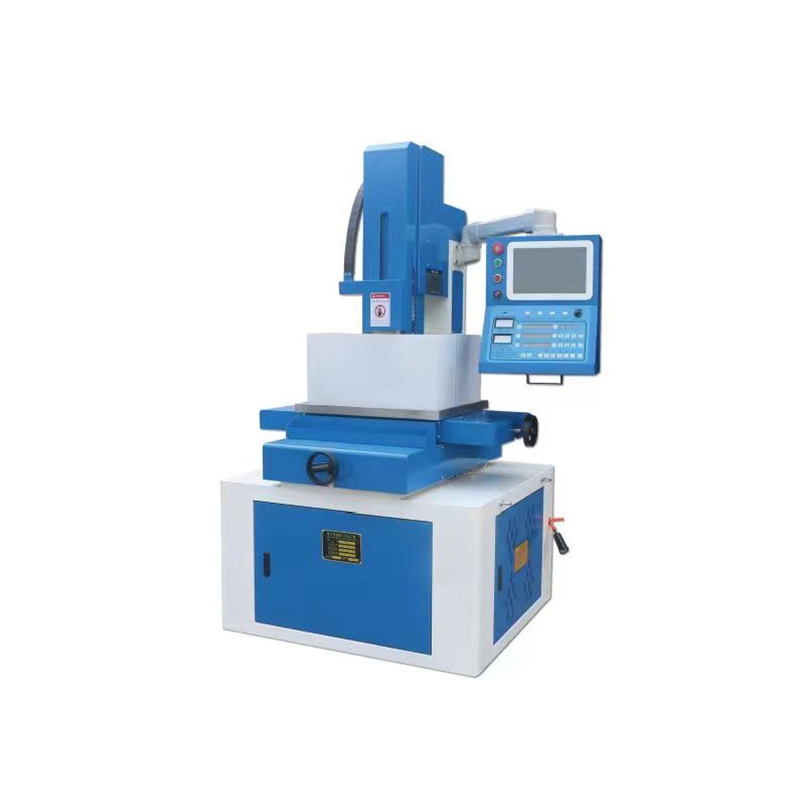

In today's competitive manufacturing landscape, selecting the right equipment is crucial for efficiency and productivity. One of the most versatile tools available is the multifunctional precision punching machine. At Dingxing, we offer the CKJ35 Multi-function Precision Punching Machine, designed to meet diverse processing needs with precision and reliability. This blog will guide you through the key considerations when choosing a multifunctional precision punching machine for your business.

Understanding Your Needs

Before diving into specific models, it's essential to assess your operational requirements. Consider the following factors:

1. Material Types: Determine the types of materials you will be processing. The CKJ35 is capable of working with various conductive materials, including stainless steel, hardened steel, copper, aluminum, and hard alloys.

2. Hole Specifications: Identify the size and depth of holes you need to create. The CKJ35 can process deep small holes with diameters ranging from 0.2mm to 3mm, making it suitable for applications like molds and threading holes.

3. Production Volume: Evaluate your production volume to ensure that the machine can meet your output demands without compromising quality.

Key Features to Look For

When selecting a multifunctional precision punching machine, consider these critical features:

1. Precision and Accuracy: Look for machines that utilize advanced technologies like servo motors and ball screws, which enhance accuracy in punching operations. The CKJ35 features precision linear guides to ensure high processing accuracy.

2. Versatility: A multifunctional machine should be able to handle various tasks beyond just punching, such as etching broken drill bits or taps without damaging existing threads or holes.

3. Ease of Use: User-friendly interfaces and automated functions can significantly reduce training time and operational errors. The CKJ35 offers one-key processing for convenience.

4. Safety Features: Ensure that the machine has adequate safety measures in place, such as emergency stop buttons and protective enclosures around moving parts.

5. Maintenance Requirements: Choose a machine that is easy to maintain and service. The CKJ35 is designed with durability in mind, featuring a robust construction that withstands wear and tear.

Evaluating Performance Metrics

Performance metrics are vital when comparing different models:

1. Processing Speed: Assess the maximum punching speed of the machine; for instance, the CKJ35 can achieve speeds of 30-60mm/rpm.

2. Depth-to-Diameter Ratio: A higher ratio indicates greater capability for deep hole processing relative to diameter; the CKJ35 boasts a maximum depth-to-diameter ratio of 300:1.

3. Power Consumption: Consider the rated power of the machine; the CKJ35 operates at 3KW, which should align with your energy efficiency goals.

Conclusion

Choosing the right multifunctional precision punching machine can significantly impact your manufacturing efficiency and product quality. By evaluating your specific needs, considering essential features, and assessing performance metrics, you can make an informed decision that aligns with your business objectives. At Dingxing, our CKJ35 Multi-function Precision Punching Machine is designed to deliver exceptional performance across various applications, ensuring you stay competitive in your industry. If you have any questions or need assistance in selecting the right machine for your needs, feel free to reach out!