In the rapidly evolving renewable energy sector, wind energy has emerged as a leading source of clean power. As the demand for wind energy continues to grow, so does the need for efficient and reliable manufacturing processes, particularly in the production of wind towers. One of the critical components in this manufacturing process is the welding equipment used to construct these towering structures.

Understanding Wind Tower Welding

Wind towers are typically made from steel, which requires robust welding techniques to ensure structural integrity and durability. The welding process involves joining metal parts together using heat and pressure, which can be achieved through various methods such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and submerged arc welding. Each method has its advantages and is suited for different applications within the wind tower manufacturing process.

Importance of Choosing the Right Welding Equipment

Selecting the appropriate welding equipment is crucial for several reasons:

Quality of Welds: The strength and durability of the wind tower depend significantly on the quality of the welds. Poor welding can lead to structural failures, which can be catastrophic in wind energy applications.

Efficiency: The right equipment can enhance productivity, reducing the time and labor required for welding operations. This efficiency translates to cost savings and faster project completion.

Safety: Welding can be hazardous, and using the right equipment can minimize risks associated with the process, ensuring a safer working environment for operators.

Adaptability: Wind tower designs can vary, and having versatile welding equipment allows manufacturers to adapt to different specifications and requirements.

Key Factors to Consider When Selecting Wind Tower Welding Equipment

When choosing welding equipment for wind tower production, several factors should be taken into account:

1. Type of Welding Process

As mentioned earlier, different welding processes are suitable for various applications. Understanding the specific requirements of your wind tower design will help you determine which welding method is most appropriate. For instance:

MIG Welding: Ideal for thin materials and provides a high deposition rate, making it suitable for large-scale production.

TIG Welding: Offers greater control and is perfect for intricate welds, although it may be slower than MIG.

Submerged Arc Welding: Highly efficient for thick materials and large welds, commonly used in wind tower fabrication.

2. Equipment Specifications

When evaluating welding equipment, consider the following specifications:

Welding Current: Ensure the equipment can handle the required amperage for the materials being welded.

Voltage Range: A wider voltage range allows for more flexibility in different welding scenarios.

Duty Cycle: This indicates how long the machine can operate before needing a cooldown period. A higher duty cycle is preferable for continuous production.

3. Portability and Size

Wind tower components can be massive, and the welding equipment must be able to accommodate these dimensions. Consider whether you need stationary or portable equipment. Portable welding machines can be advantageous for on-site repairs or adjustments, while larger, stationary machines may be better suited for a dedicated manufacturing facility.

4. Automation Capabilities

Automation in welding can significantly enhance productivity and consistency. Look for equipment that offers automated features such as:

Robotic Welding: Increases precision and reduces labor costs.

CNC Controls: Allows for programmable welding paths, ensuring uniformity in welds.

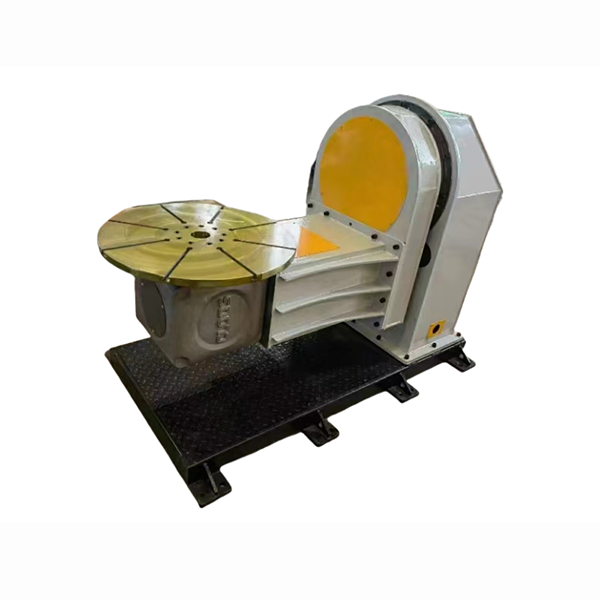

Wuxi YuanPeng Machinery: A Leader in Wind Tower Welding Equipment

Wuxi YuanPeng Machinery has established itself as a leader in the manufacturing of wind tower welding equipment. With a focus on quality and innovation, they offer a range of products designed to meet the specific needs of the wind energy sector. Here are some key features of their equipment:

Advanced Technology

Wuxi YuanPeng Machinery utilizes cutting-edge technology in their welding equipment, ensuring high precision and efficiency. Their machines are designed to handle the unique challenges of wind tower fabrication, including the ability to weld thick steel plates with ease.

Custom Solutions

Understanding that each project may have different requirements, Wuxi YuanPeng Machinery offers customized solutions tailored to the specific needs of their clients. This flexibility allows manufacturers to optimize their production processes and achieve better results.

Comprehensive Support

Wuxi YuanPeng Machinery provides extensive support to its customers, including training, maintenance, and technical assistance. This commitment to customer service ensures that manufacturers can operate their equipment effectively and efficiently.

Proven Track Record

With years of experience in the industry, Wuxi YuanPeng Machinery has built a reputation for reliability and quality. Their equipment is used by leading manufacturers in the wind energy sector, making them a trusted partner for those looking to invest in welding technology.

Conclusion

Selecting the right wind tower welding equipment is a critical decision that can impact the quality, efficiency, and safety of your manufacturing process. By considering factors such as the type of welding process, equipment specifications, portability, automation capabilities, and brand reputation, you can make an informed choice that meets your specific needs.

Wuxi YuanPeng Machinery stands out as a leading provider of wind tower welding equipment, offering advanced technology, custom solutions, and comprehensive support. By partnering with a reputable manufacturer, you can ensure that your welding operations are optimized for success in the growing wind energy market. As the demand for renewable energy continues to rise, investing in the right welding equipment will position your business for long-term growth and sustainability.