In the world of industrial manufacturing, the need for robust, durable materials that can withstand harsh environments is ever-growing. One such material that plays a pivotal role in a wide range of applications is heavy wall square tubing. Whether it’s for construction, automotive, or structural projects, heavy wall square tubing offers strength, versatility, and long-term performance.

In this guide, we’ll explore the features and advantages of heavy wall square tubing, its diverse industrial applications, and why choosing the right supplier, like TORICH, a leading manufacturer and supplier of steel tube materials, is essential for ensuring high-quality results.

What is Heavy Wall Square Tubing?

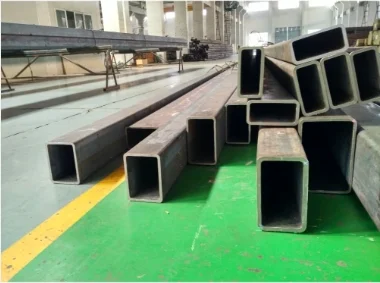

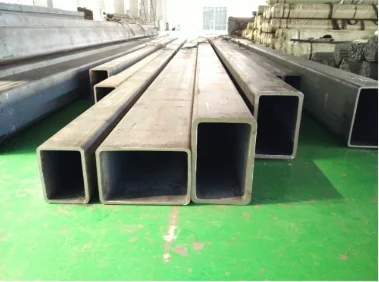

Heavy wall square tubing is a type of steel tubing that features a thicker wall than standard square tubing. The "heavy wall" designation refers to the increased thickness of the tube’s walls, which enhances its strength and durability. These tubes are typically made from high-quality steel and come in a variety of dimensions and thicknesses to suit different industrial requirements.

The square shape provides additional structural advantages over round tubing, especially in applications where uniformity in all directions is required. Heavy wall square tubing is designed to handle greater loads and resist impacts, making it ideal for high-stress environments.

Key Features of Heavy Wall Square Tubing

1. Increased Strength and Durability

The thicker walls of heavy wall square tubing provide increased strength, making it suitable for applications that require high load-bearing capacity. It’s designed to withstand external pressures, heavy loads, and mechanical stresses that would compromise the integrity of thinner tubing.

This durability is one of the reasons why heavy wall square tubing is often used in applications where safety and longevity are a priority, such as in construction and infrastructure projects.

2. Superior Resistance to Corrosion

Many heavy wall square tubes are made from carbon steel, stainless steel, or alloy steel—materials known for their resistance to corrosion. Stainless steel, in particular, offers excellent resistance to rust and chemical corrosion, making it suitable for use in harsh environments like marine or chemical processing industries.

By choosing the right material and protective coatings, such as galvanization or powder coating, the tubing’s resistance to corrosion can be further enhanced, extending its lifespan.

3. Versatile Design and Dimensions

Heavy wall square tubing comes in a variety of sizes, allowing it to be tailored to specific project needs. The uniform square shape provides a higher degree of versatility in terms of structural design. The tubing can be used as framing, supports, rails, or even as a structural component within larger systems.

Moreover, manufacturers can customize dimensions to meet specific engineering and construction requirements, which makes it suitable for diverse industries—from structural engineering to machinery and equipment manufacturing.

4. Enhanced Load Distribution

The square shape, in combination with the thick walls, helps in distributing load evenly across the structure. This makes heavy wall square tubing a good choice for applications that need to support heavy machinery, large panels, or other weight-bearing structures.

In fact, it is often preferred over round tubing for certain structural applications because of the ability to transfer loads effectively across the four sides of the tubing, reducing the risk of failure due to stress concentrations.

5. Cost-Effective and Easy to Fabricate

Although heavy wall square tubing can be more expensive than standard tubing, it offers a significant return on investment due to its enhanced performance and versatility. Its ease of fabrication also contributes to cost-effectiveness. Fabricators can weld, cut, or drill the tubing to create custom solutions, making it suitable for a wide range of projects without requiring expensive specialized tools.

Applications of Heavy Wall Square Tubing

Heavy wall square tubing is used in a broad spectrum of industries, including:

Construction: Used for building frameworks, structural supports, and columns. Its strength and ability to bear heavy loads make it an ideal choice for high-rise buildings and large infrastructure projects.

Automotive and Transportation: Employed in the manufacturing of vehicle frames, chassis, and support beams due to its durability and impact resistance.

Energy and Power: Often used in the construction of pipelines, drilling rigs, and other energy infrastructure due to its ability to withstand harsh environments.

Agricultural Equipment: Its strength makes it useful in building durable machinery and equipment for agricultural applications.

Furniture and Architectural Designs: Heavy wall square tubing is also used in creating sturdy and stylish furniture pieces, railing systems, and decorative elements, offering both functionality and aesthetic appeal.

Why Choose TORICH for Heavy Wall Square Tubing?

When it comes to sourcing heavy wall square tubing, the quality of the materials and the expertise of the supplier are critical. TORICH, a leading manufacturer and supplier of steel tube materials, stands out as a trusted provider due to its commitment to quality, precision, and customer satisfaction. Here's why TORICH is the right choice for your industrial tubing needs:

1. High-Quality Materials

TORICH specializes in providing high-quality steel tube materials, including heavy wall square tubing, made from premium-grade materials like carbon steel, stainless steel, and alloy steel. Their products are manufactured in compliance with international standards, ensuring superior strength, durability, and performance in all applications.

2. Customization and Flexibility

One of TORICH’s key strengths is its ability to offer customized solutions. They work closely with clients to understand specific requirements and can manufacture heavy wall square tubing in various sizes, thicknesses, and finishes. Whether you need small quantities or large-scale production runs, TORICH is equipped to meet your needs efficiently.

3. Comprehensive Service Offering

TORICH provides end-to-end services, from design and manufacturing to delivery. This means that customers can expect a smooth, seamless experience from start to finish. Additionally, TORICH ensures that its products undergo rigorous testing and quality control to ensure they meet the highest standards before they reach the customer.

4. Industry Expertise

With years of experience in the steel industry, TORICH’s team brings invaluable technical knowledge to every project. Their expertise ensures that customers receive accurate guidance on material selection, fabrication techniques, and application-specific requirements.

5. Global Reach and Reliable Delivery

As a globally recognized supplier, TORICH has established a robust distribution network that ensures timely and reliable delivery of products to clients around the world. Their ability to meet deadlines, even for large and complex orders, makes them a trusted partner for industries with tight project timelines.

Conclusion

Heavy wall square tubing is an essential material for a wide range of industrial applications, offering strength, durability, and versatility. From construction to automotive and energy industries, it provides reliable support and structural integrity. By choosing a trusted supplier like TORICH, manufacturers and engineers can ensure that they are using top-quality steel tubing that meets their project needs.

With TORICH’s focus on quality materials, customization, and comprehensive services, industries can rest assured that their heavy wall square tubing will perform optimally and contribute to the long-term success of their projects. Whether you are looking for durable tubing for construction, manufacturing, or specialized applications, TORICH is the partner you can rely on to deliver high-quality solutions that stand the test of time.

From Design to Implementation: The Role of Heavy Wall Square Tubing in Various Industries