In today’s highly competitive manufacturing landscape, precision and efficiency are paramount. Whether you’re in sheet metal fabrication, automotive, or industrial manufacturing, the quality of the tools you use directly impacts your production outcomes. One tool that has made waves in the industry for its reliability and performance is the Amada Punch 30°.

But what makes the Amada Punch 30° a game-changer for your manufacturing needs? In this post, we’ll explore the key reasons why Amada’s punches are an essential addition to your shop floor and how AE Tooling, a leading manufacturer of high-end bending tools, plays a role in optimizing your overall metalworking operations.

1. Precision and Accuracy at Every Stroke

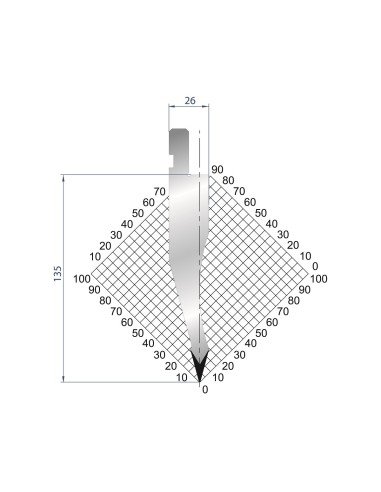

Amada is well-known for engineering punches that deliver exceptional precision, and the 30° punch is no exception. With its unique angle, it allows for clean, accurate perforations and cuts, making it ideal for a variety of sheet metal applications. Whether you're working with thin or thick gauge materials, the Amada Punch 30° ensures that every cut is smooth and precise, minimizing the need for rework and enhancing your overall production efficiency.

In industries that rely on high tolerance and complex shapes—such as aerospace, automotive, and electronics—having a reliable punch that can consistently achieve tight tolerances is essential. The Amada Punch 30° offers manufacturers the confidence that their parts will meet the highest quality standards, reducing waste and improving final product quality.

2. Durability and Long-Term Performance

When it comes to tools used in high-demand environments, durability is a must. The Amada Punch 30° is designed to withstand the heavy wear and tear of constant use, thanks to its high-grade materials and advanced manufacturing processes. This durability ensures that your tool performs consistently over the long term, reducing downtime caused by tool failure or the need for frequent replacements.

At AE Tooling, we understand the importance of high-performance tools in achieving efficiency and reducing operating costs. That’s why we collaborate with industry leaders like Amada to ensure that our bending tools are also built with durability in mind. We use cutting-edge materials and design techniques to make sure that the tools used in your shop are reliable, minimizing downtime and increasing your shop’s overall productivity.

3. Enhanced Efficiency and Speed

Time is money in any manufacturing process, and the Amada Punch 30° is designed with this in mind. The sharp 30° angle facilitates quicker penetration, which results in faster cycle times and greater throughput. Whether you're performing a high volume of small parts or larger, more intricate jobs, the increased speed allows you to meet tight deadlines while maintaining high-quality standards.

At AE Tooling, we believe in the power of efficiency, not just for punches, but for all manufacturing tools. Our range of high-end bending tools is also optimized for speed and precision, helping you cut down on unnecessary delays in the production process. With the right combination of punches and bending tools, manufacturers can streamline their entire operation from start to finish.

4. Reduced Tooling Costs and Maintenance

High-quality tooling can be an investment, but the long-term savings are worth it. By using the Amada Punch 30°, you’re investing in a tool that requires less frequent maintenance compared to lower-quality alternatives. The robust construction and engineered precision reduce wear and tear, meaning that you’ll spend less time and money on maintenance, adjustments, and replacements.

Furthermore, the Amada Punch 30° is compatible with various CNC punching machines, which increases its versatility and ensures that it can be used across a wide range of applications. By investing in high-end tools, manufacturers can reduce their total tooling costs over time—something that AE Tooling always emphasizes when creating solutions for bending machines.

We believe in providing manufacturers with tools that not only perform well but also offer significant savings in terms of longevity and maintenance. AE Tooling’s high-quality bending tools are no exception. Designed for durability and minimal maintenance, our tools work seamlessly alongside Amada’s punches to optimize your overall tool life and operational efficiency.

5. Versatility Across Various Applications

One of the biggest advantages of the Amada Punch 30° is its versatility. It can be used across a wide range of applications, from simple perforations to more complex custom jobs. Whether you're working with aluminum, steel, or other materials, this punch adapts to your needs, offering manufacturers flexibility in their production process.

At AE Tooling, versatility is key. Our range of advanced bending tools is designed to work across multiple industries, whether you're in automotive, aerospace, or HVAC manufacturing. We specialize in creating tools that can handle a variety of materials and complex bends, making sure that your shop floor is ready to take on any challenge.

6. Synergy with AE Tooling’s High-End Bending Solutions

While the Amada Punch 30° brings immense value to your punching operations, it works best when paired with equally high-quality bending tools. AE Tooling specializes in developing premium bending tools designed specifically for bending machines and manufacturing companies. Our tools are precision-engineered to work in harmony with punching tools like the Amada Punch, allowing you to perform both punching and bending tasks with unmatched efficiency and accuracy.

Whether you’re creating intricate parts for the aerospace sector or fabricating high-strength components for industrial applications, the combination of Amada Punches and AE Tooling bending solutions ensures that your operation is optimized for maximum performance and productivity.

Conclusion

The Amada Punch 30° is undeniably a game-changer for manufacturers seeking precision, speed, and durability. Its ability to deliver clean, accurate cuts at a faster rate, while being built to last, makes it an essential tool for high-efficiency manufacturing. When combined with AE Tooling’s premium bending tools, your shop is equipped to handle a wide range of applications, all while maintaining a high standard of performance and reducing operational costs.

Investing in quality tools like the Amada Punch 30° and AE Tooling’s bending solutions isn’t just about improving your processes—it’s about setting your business up for long-term success. If you’re ready to elevate your production capabilities, consider integrating Amada’s punches and AE Tooling’s high-end bending tools into your manufacturing workflow today.