In the modern era of energy production, industries are increasingly looking for more efficient and environmentally friendly technologies. One such solution that has gained significant attention is the Circulating Fluidized-Bed (CFB) unit. Known for its versatility, fuel efficiency, and reduced environmental impact, CFB technology is playing a key role in revolutionizing energy production. For companies like Chem-Unit Technologies Co. Ltd., which specializes in modular test units, pilot-scale systems, and production units, CFB technology presents a promising opportunity to drive innovation and meet the growing demand for sustainable energy.

What is Circulating Fluidized-Bed Technology?

At its core, Circulating Fluidized-Bed (CFB) technology involves the combustion of solid fuel particles in an upward flow of gas, which causes the solid particles to behave like a fluid. This "fluidized" state improves heat transfer and combustion efficiency, leading to more complete fuel combustion and reduced emissions. The term "circulating" refers to the continuous motion of these particles, which allows for better fuel utilization and improved control over the combustion process.

CFB systems are flexible, capable of handling a wide range of fuels such as coal, biomass, waste, and even industrial by-products. This makes them highly adaptable to different industrial needs, offering both environmental and economic benefits.

The Key Benefits of CFB Units in Energy Production

Improved Energy Efficiency One of the most compelling reasons why CFB units are becoming increasingly popular is their high energy efficiency. CFB systems achieve better heat transfer due to the continuous circulation of particles, which leads to more complete combustion of fuel. This not only results in lower fuel consumption but also improves the overall energy output, making it more cost-effective for businesses.

Reduced Environmental Impact The reduced emissions from CFB technology are another standout feature. By operating at lower temperatures than traditional combustion systems, CFB units produce fewer harmful gases such as nitrogen oxides (NOx) and sulfur oxides (SOx), which are major contributors to air pollution and acid rain. Additionally, CFB systems can incorporate advanced flue gas cleaning technologies to further minimize emissions, making them one of the most environmentally friendly energy production solutions available.

Fuel Flexibility Another significant advantage of CFB technology is its ability to use a wide range of fuels. While traditional coal-fired power plants are limited to using coal as a primary fuel source, CFB systems can handle coal, biomass, and even municipal solid waste (MSW). This flexibility not only provides more sustainable options but also allows industries to take advantage of low-cost waste materials as fuel, contributing to waste management and reducing landfill burdens.

Sustainability and Waste-to-Energy Potential CFB units are particularly well-suited for turning waste into energy. The ability to use industrial by-products, agricultural residues, and waste materials as fuel helps address both energy production and waste management challenges. By transforming waste into valuable energy, CFB technology contributes to a circular economy, helping reduce the environmental impact of waste disposal and supporting renewable energy goals.

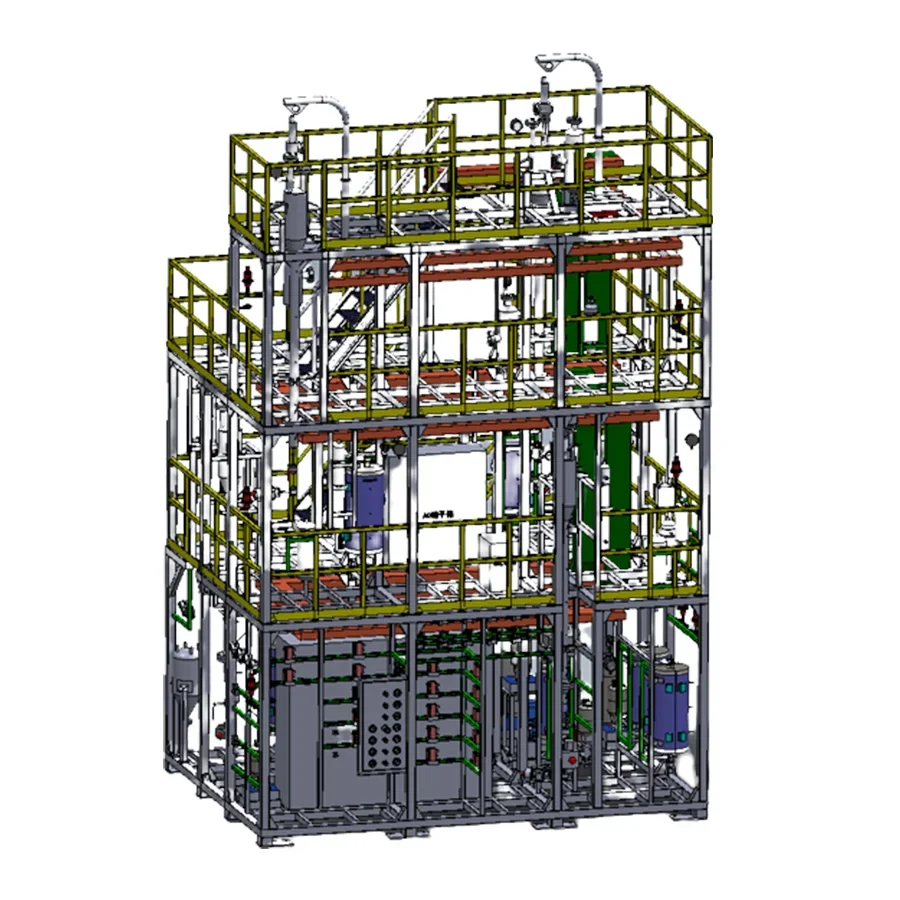

Scalability and Modular Design CFB units are highly scalable, meaning they can be customized to fit the specific needs of different industries. Whether you're looking to power a small industrial plant or a large-scale energy facility, CFB systems can be designed and sized accordingly. Companies like Chem-Unit Technologies Co. Ltd., which specialize in modular test and pilot-scale units, make it easier for businesses to evaluate CFB technology before committing to a large-scale implementation.

Chem-Unit Technologies Co. Ltd.: A Leader in CFB Innovation

As a key player in the field, Chem-Unit Technologies Co. Ltd. is dedicated to advancing CFB technology by offering modular systems that provide valuable insights into energy production processes. Specializing in the design, development, and implementation of test units, pilot systems, and production-scale solutions, Chem-Unit Technologies helps businesses better understand the feasibility of incorporating CFB technology into their operations.

By offering modular test and pilot-scale systems, Chem-Unit Technologies provides a low-risk way for companies to experiment with CFB technology in real-world conditions. These systems enable businesses to optimize the performance of their energy production processes before scaling up, ensuring that they achieve maximum efficiency and cost-effectiveness.

Why CFB Units are the Future of Energy Production

With the global shift toward cleaner and more sustainable energy solutions, Circulating Fluidized-Bed technolation of high energy efficiency, reduced emissions, and fuel flexibility makes CFB systems a game-changer for industries looking to reduce their environmental impact while maintaining energy production levels.

Furthermore, the ability to use waste materials as fuel provides an added layer of sustainability, making CFB systems integral to the future of waste-to-energy technologies. As industries around the world seek ways to optimize their energy production and reduce their carbon footprint, CFB units are likely to become an increasingly important component of the energy landscape.

Final Thoughts

As energy demands continue to rise and environmental concerns become more pressing, Circulating Fluidized-Bed technology offers a sustainable and efficient solution for industries looking to innovate. Whether through improved energy efficiency, reduced emissions, or greater fuel flexibility, CFB units provide significant advantages for businesses in the energy sector.

For companies looking to explore the potential of CFB technology, working with specialists like Chem-Unit Technologies Co. Ltd. can provide valuable expertise in designing modular, scalable systems that optimize performance and contribute to a greener future. By adopting CFB technology, businesses not only stay ahead of the curve in energy production but also play an essential role in creating a more sustainable world.

In conclusion, the integration of Circulating Fluidized-Bed technology in energy production is a critical step toward achieving both economic and environmental goals. With the support of Chem-Unit Technologies, industries can harness the full potential of CFB systems to build a more sustainable and energy-efficient future.