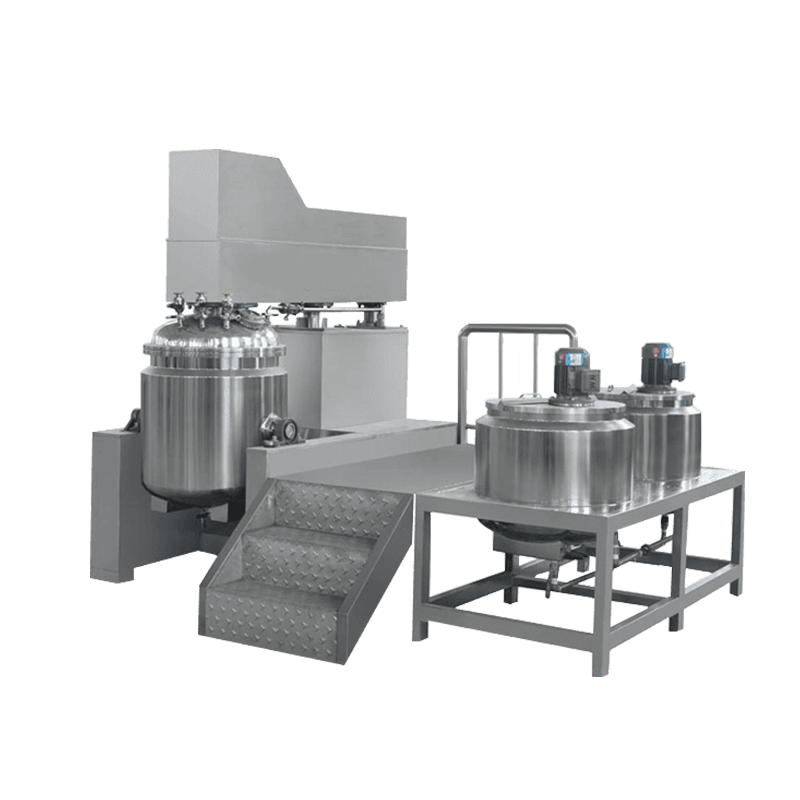

In modern industrial manufacturing, achieving high-quality, uniform, and stable emulsions is essential for various industries, including cosmetics, pharmaceuticals, food processing, and chemicals. The vacuum emulsifying homogenizer mixer is a crucial piece of equipment designed to enhance the mixing, emulsification, and homogenization processes. As a company specializing in mechanical design and manufacturing, Orisun provides advanced vacuum emulsifying homogenizer mixers tailored to meet industrial needs. This article explores the key functions, applications, and benefits of this equipment.

What is a Vacuum Emulsifying Homogenizer Mixer?

A vacuum emulsifying homogenizer mixer is an industrial machine that combines emulsification, mixing, homogenization, and vacuum deaeration to create stable and high-quality emulsions. It is widely used in industries requiring fine particle reduction and uniform distribution of substances.

Key Components:

Vacuum System: Removes air bubbles and prevents oxidation during mixing.

Homogenizer: Breaks down particles to create fine, stable emulsions.

Mixing System: Combines ingredients thoroughly to ensure uniform consistency.

Heating & Cooling System: Allows precise temperature control for different formulations.

Control System: Provides automated or manual adjustments for precise processing.

Industrial Applications of the Vacuum Emulsifying Homogenizer Mixer

1. Cosmetics & Personal Care Industry

Vacuum emulsifying homogenizers are widely used in producing:

Creams and lotions

Shampoos and conditioners

Makeup products (foundations, serums, and balms)

These mixers ensure uniform texture, improved product stability, and enhanced absorption properties.

2. Pharmaceutical Industry

The pharmaceutical sector relies on this equipment for:

Ointments and gels

Medical emulsions and syrups

Injectable formulations

The vacuum function helps remove air bubbles, ensuring sterile and high-quality pharmaceutical products.

3. Food and Beverage Industry

In food production, vacuum emulsifying mixers assist in making:

Sauces and dressings

Dairy products like creams and yogurt

Processed food emulsions (mayonnaise, spreads, and flavorings)

The mixer enhances texture, consistency, and shelf-life by preventing oxidation and microbial contamination.

4. Chemical Industry

For chemical processing, these mixers are used in:

Paints and coatings

Lubricants and adhesives

Household and industrial cleaning products

The homogenization process ensures even distribution of chemical components for optimal performance.

Benefits of Using a Vacuum Emulsifying Homogenizer Mixer

1. Improved Product Stability and Consistency

The homogenization process ensures even particle distribution, leading to high-quality and stable final products with extended shelf life.

2. Air-Free and Contaminant-Free Processing

The vacuum system prevents air bubbles and oxidation, which is essential for sensitive formulations like pharmaceuticals and cosmetics.

3. Enhanced Mixing Efficiency

Advanced mixing and homogenization technologies reduce production time while achieving precise results, increasing overall efficiency and productivity.

4. Precise Temperature and Process Control

With automated temperature control, the mixer ensures that ingredients are processed under optimal conditions, preventing overheating or degradation.

5. Versatile and Customizable Solutions

Different industries require varying levels of homogenization and emulsification. Orisun’s vacuum emulsifying homogenizers come in customizable designs to meet specific manufacturing needs.

Why Choose Orisun?

As an experienced company specializing in mechanical design and manufacturing, Orisun offers high-performance vacuum emulsifying homogenizer mixers designed for efficiency, precision, and durability. Our machines are built to industry standards, ensuring:

Superior quality and performance

Customizable solutions for various applications

Reliable after-sales support and technical assistance

Energy-efficient and user-friendly operation

Conclusion

The vacuum emulsifying homogenizer mixer is an essential tool in industries that require precise emulsification, mixing, and homogenization. With its advanced technology, it ensures product quality, consistency, and efficiency in manufacturing. Orisun provides top-tier vacuum emulsifying homogenizers, designed to meet industrial demands and improve production processes.

For more information on Orisun’s innovative mixing solutions, contact us today and discover how we can enhance your manufacturing process.