Selecting the right HTD (High Torque Drive) timing pulley is crucial for ensuring efficient and reliable power transmission in various mechanical applications. Whether you are working with industrial machinery, automation systems, or robotics, choosing the correct pulley can significantly impact performance and durability.

As a specialist in high-precision transmission components, Hetuoda Machinery Manufacturing provides a wide range of timing pulleys, gear plates, tensioners, gears, and custom-machined parts, along with OEM services to meet industry-specific requirements.

This guide will outline key factors to consider when selecting an HTD timing pulley for your power transmission needs.

1. Understanding HTD Timing Pulleys

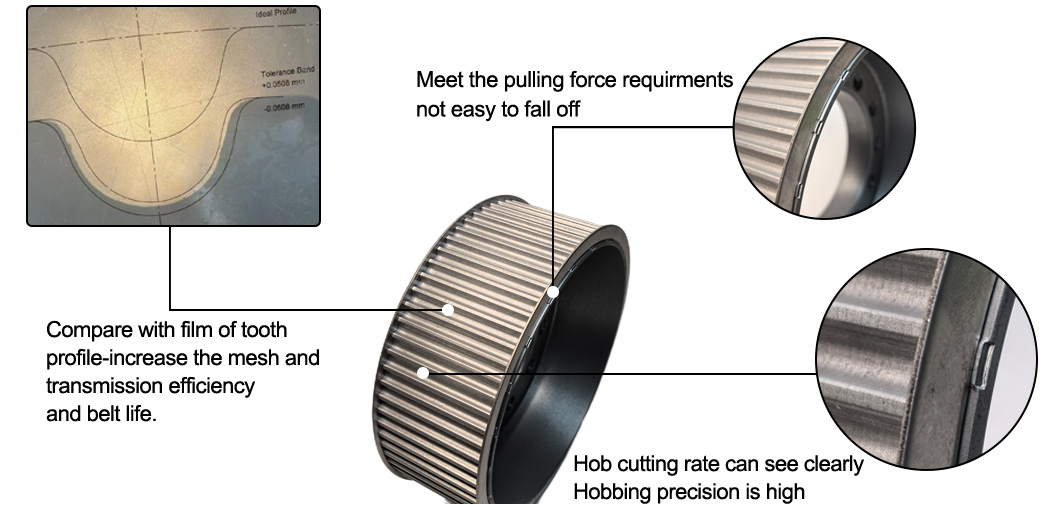

HTD timing pulleys are designed for synchronous belt drive systems, offering precise power transmission with minimal slippage. Compared to traditional belt systems, HTD pulleys feature a curved tooth profile, improving engagement and increasing load capacity. These pulleys are commonly used in high-torque applications, such as CNC machinery, conveyor systems, and automated production lines.

2. Key Factors to Consider When Choosing an HTD Timing Pulley

Pulley Size and Pitch

-

The pitch (distance between adjacent teeth) should match the HTD timing belt to ensure proper meshing.

-

Common HTD pitches include 3M, 5M, 8M, and 14M, with larger pitches designed for higher torque transmission.

-

The number of teeth and pulley diameter influence speed ratio and power transmission efficiency.

Material Selection

-

Aluminum: Lightweight and resistant to corrosion, ideal for high-speed applications.

-

Steel: High-strength and durable, suitable for heavy-load and high-torque environments.

-

Plastic (Engineering-grade): Cost-effective for lighter applications with moderate loads.

-

Customized Materials: Hetuoda Machinery offers specialized materials based on application-specific needs.

Bore Type and Shaft Compatibility

-

The pulley bore must match the shaft diameter for a secure fit.

-

Common options include plain bore, keyway bore, and taper-lock bore.

-

Custom machining services are available at Hetuoda Machinery for precise fitment.

Flange Configuration

-

Flanged pulleys help guide the timing belt and prevent lateral movement.

-

Options include single-flange, double-flange, or no-flange, depending on system design.

Load and Torque Requirements

-

Higher torque loads require pulleys with stronger materials and optimized tooth profiles.

-

Assess the mechanical power transmission needs to determine the appropriate pulley specifications.

Environmental Considerations

-

Operating conditions such as temperature, humidity, and exposure to chemicals should be considered.

-

Specialized coatings and materials can improve corrosion resistance, wear resistance, and heat tolerance.

3. Why Choose Hetuoda Machinery Manufacturing for HTD Timing Pulleys

As a trusted manufacturer of high-precision power transmission components, Hetuoda Machinery Manufacturing ensures top-tier quality and performance in every product.

Advantages of Hetuoda Machinery’s HTD Timing Pulleys

-

High-precision CNC machining for superior accuracy and smooth belt engagement.

-

Diverse material options, including aluminum, steel, and custom-engineered materials.

-

Custom OEM solutions tailored to specific industry applications.

-

Strict quality control standards to ensure durability and consistency.

-

Comprehensive product offerings, including timing pulleys, tensioners, gears, and more.

4. Conclusion

Choosing the right HTD timing pulley plays a critical role in ensuring efficient, precise, and long-lasting power transmission. By considering factors such as pitch, material, bore compatibility, and load requirements, you can optimize performance and reduce maintenance costs.

For customized, high-quality HTD timing pulleys, Hetuoda Machinery Manufacturing is a reliable partner, offering expert engineering and precision manufacturing to meet your needs.

If you need professional guidance in selecting the best HTD timing pulley for your system, contact Hetuoda Machinery Manufacturing today for expert support and tailored solutions.